Exploring the Cutting-Edge Ultrasonic Technology in Flow Meters

In the dynamic world of flow measurement, the advent of ultrasonic technology has been a game-changer, particularly with the development of the clamp-on ultrasonic flowmeter. This innovative tool has revolutionized how industries measure fluid flow, offering a blend of accuracy, convenience, and versatility that traditional meters can’t match. As an industry specialist in ultrasonic clamp-on flow metering technology, I’ve witnessed first-hand the transformative impact these devices have had across various sectors.

The Essence of Ultrasonic Flow Metering

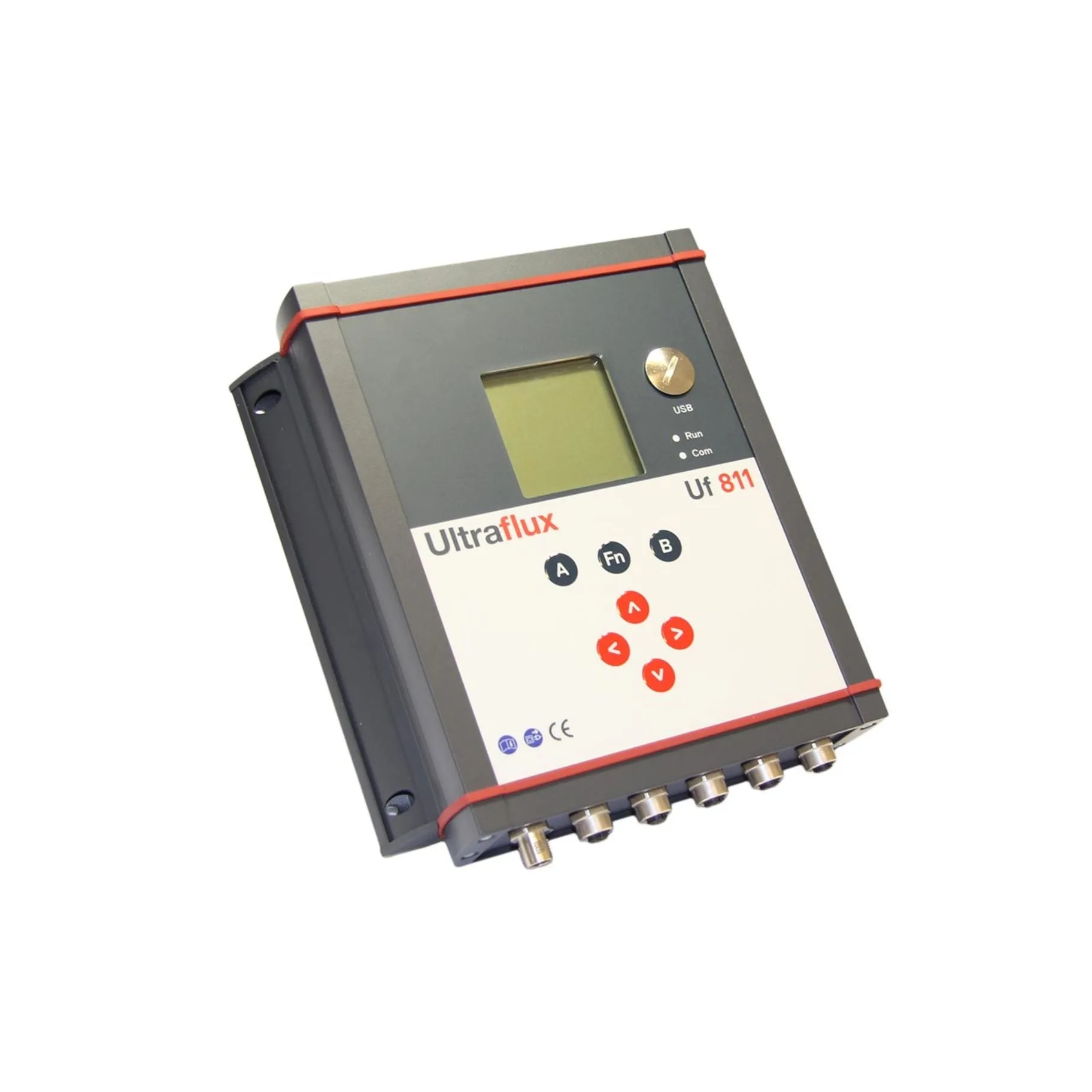

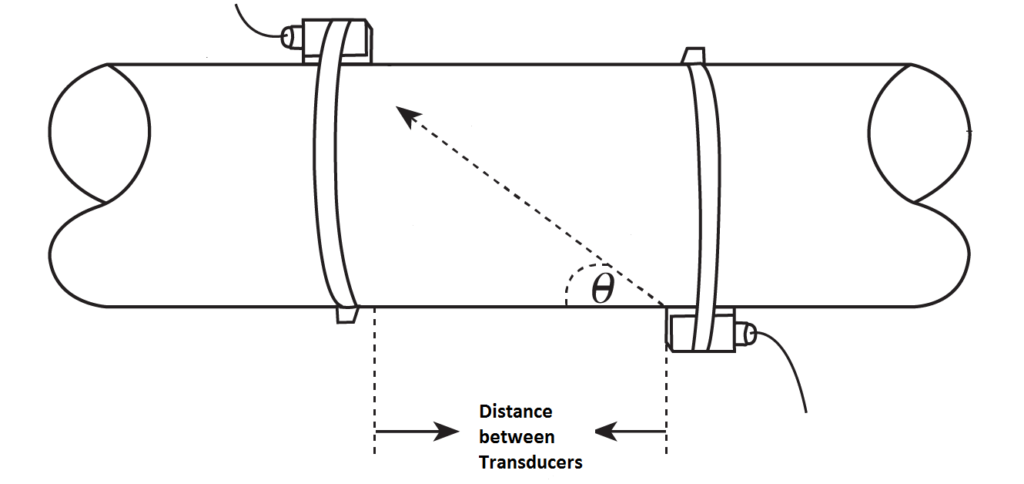

At its core, a clamp-on ultrasonic flowmeter operates on a simple yet ingenious principle. It uses ultrasonic waves, which are sound waves at a frequency higher than humans can hear, to measure the flow rate of a liquid in a pipe. The device comprises two main components: transducers and an electronic unit. The transducers, clamped onto the outside of the pipe, emit ultrasonic pulses through the pipe wall and the flowing fluid. By measuring the time it takes for the sound waves to travel with and against the flow of the liquid, the meter calculates the flow rate with remarkable precision.

Advantages of Clamp-On Ultrasonic Flowmeters

The clamp-on design of these ultrasonic meters offers several compelling advantages. Firstly, it’s non-invasive; there’s no need to cut pipes or halt operations for installation, making it an ideal solution for industries where process continuity is critical. This design also means reduced maintenance and no pressure drop across the meter.

Another significant advantage is the versatility. Clamp-on ultrasonic flowmeters can handle various liquids, from water and wastewater to chemicals and oils, and they’re adaptable to different pipe sizes and materials. This flexibility makes them a go-to choice for diverse applications, from HVAC and energy management to process control and water conservation.

Accuracy and Reliability

Accuracy is paramount in flow measurement, and here, ultrasonic technology shines. These meters offer high accuracy, typically within ±1-2% of the flow rate. They’re also reliable over a wide range of flow velocities and temperatures, ensuring consistent performance under varying conditions. Advanced models come equipped with sophisticated diagnostics and real-time monitoring capabilities, enhancing their functionality.

The Future of Flow Measurement

As we look to the future, the role of clamp-on ultrasonic flowmeters is set to expand. With the integration of IoT and advancements in data analytics, these meters are evolving into smart devices capable of providing valuable insights for process optimization and predictive maintenance.

In conclusion, the clamp-on ultrasonic flowmeter represents a significant leap forward in flow measurement technology. Its non-invasive nature, versatility, accuracy, and potential for smart integration make it an indispensable tool in modern industry. As we continue to explore the possibilities of ultrasonic technology, its impact on efficiency, cost-saving, and environmental sustainability is undeniable. The future of flow measurement is here, and it’s ultrasonic.