Best Aggregate Moisture Probe for Optimal Concrete Production

SONO-VARIO Xtrem® Aggregate Moisture Probe is a superior solution for measuring real-time moisture in highly abrasive and coarse aggregates like granite, recycle, gravel, rock, crushed stone, and RAP, with diameters up to 1-1/4 inches. In the realm of aggregate processing, precision is paramount. Moisture content, particularly in abrasive and coarse aggregates, can significantly impact the quality and performance of concrete and asphalt production.

The Technology Behind Our Xtrem® Aggregate Moisture Probe

At the core of this innovation lies the groundbreaking TRIME® TDR technology. This patented advancement penetrates deep into material volumes, providing highly accurate and repeatable moisture measurements. With over two decades of expertise backing it, the SONO-VARIO Xtrem® Probe ensures consistency and precision in aggregate and fresh concrete applications like never before.

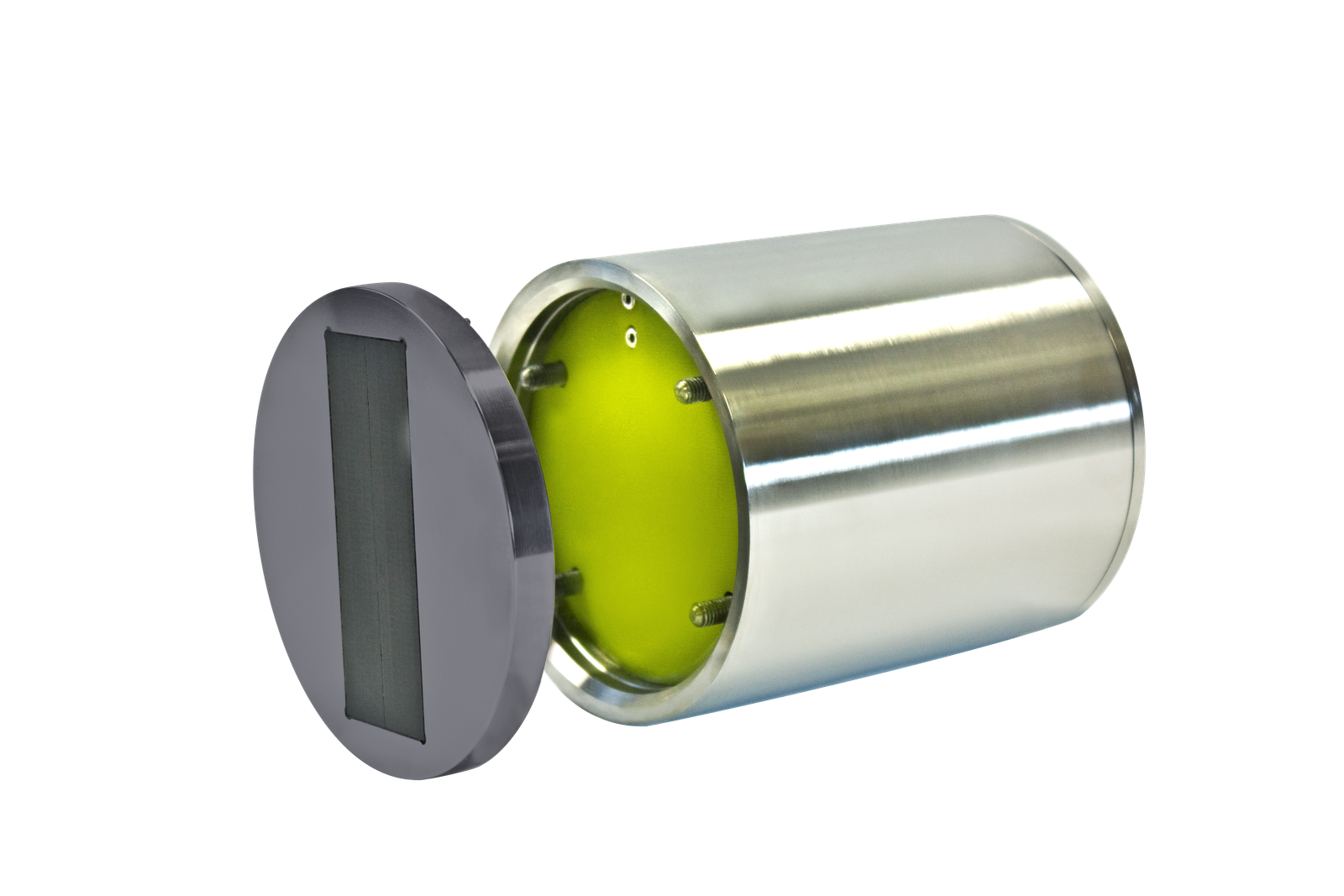

Built to Endure: The Sensor Head of the Xtrem® Aggregate Moisture Probe

But it’s not just about accuracy; durability is equally crucial in demanding environments. The sensor head of the Xtrem® Probe is meticulously crafted from high-quality ceramic, designed to withstand the relentless abrasion encountered in aggregate processing. This rugged exterior houses intelligent electronics armed with advanced algorithms and filters, automatically calibrating and adapting to surface abrasion to maintain peak performance.

Aggregate Moisture Probe with Replaceable Sensor Head

What sets the SONO-VARIO Xtrem® Probe apart is its replaceable sensor head feature. Unlike conventional probes, which require the entire unit to be replaced if the sensor head succumbs to wear, this innovation extends maintenance intervals and saves valuable time and resources, enhancing operational efficiency. Learn more about the benefits of our replaceable sensor head feature here.

Temperature Compensation and Calibration Options

Precision is embedded at every level of the Xtrem® Probe. Equipped with a built-in temperature sensor and automatic temperature compensation, real-time material temperature readings ensure the highest industry accuracy. With 15 pre-programmed standard linear calibrations, users can tailor measurement settings to suit various material types, aligning perfectly with specific requirements. Discover our range of calibration options and how they ensure precise moisture measurements for various material types here.

Seamless Integration for Optimal Performance

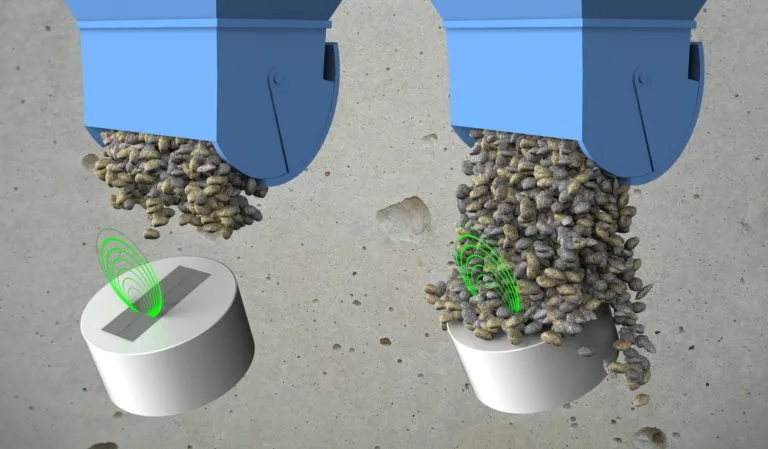

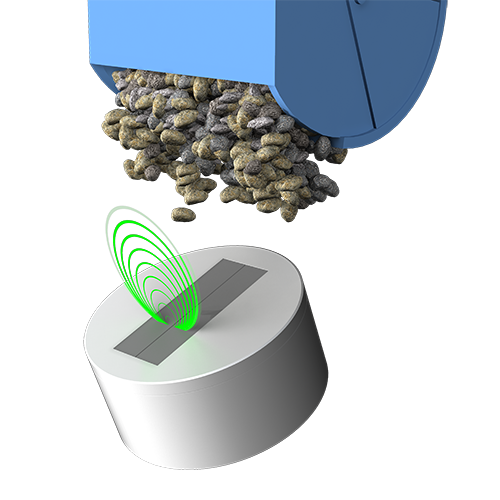

Seamless integration is another hallmark of the Xtrem® Probe. Offering a range of interface options for data transfer, including analog outputs and RS485, ensures compatibility with various systems and applications. Whether for online process moisture measurement or installations on conveyors, belts, or hoppers, the SONO-VARIO Xtrem® Aggregate Moisture Probe delivers exceptional performance every time.

Top 6 Applications of Aggregate Moisture Probe in Concrete and Asphalt Production

(1) Batching or Weighing:

The SONO-VARIO Xtrem® Aggregate Moisture Probe plays a crucial role in batching and weighing processes during concrete and asphalt production. Accurate moisture measurements of aggregates ensure precise batching and weighing, allowing producers to maintain consistent mix proportions. By integrating the probe into batching systems, producers can automate the process, reducing human error and optimizing material usage. This ensures that each batch meets quality standards and delivers uniform performance in the final product.

(2) Controlling Aggregate Moisture Content:

Controlling the moisture content of aggregates is critical in concrete and asphalt production to achieve uniformity and consistency in the final product. The Xtrem® Probe allows producers to monitor and adjust aggregate moisture levels in real time, ensuring that the mix remains within specified tolerances for optimal performance.

(3) Preventing Over-Mixing and Segregation:

In the mixing stage of concrete and asphalt production, maintaining optimal moisture levels in aggregates is essential for achieving homogeneous mixtures. The Xtrem® Probe provides real-time moisture data, allowing producers to adjust mixing parameters accordingly. By controlling moisture content during mixing, producers prevent issues such as segregation and ensure uniform distribution of materials throughout the mixture. This results in improved product quality, strength, and durability.

(4) Reducing Energy Consumption:

Excess moisture in aggregates requires additional energy to evaporate during the mixing and curing processes, leading to increased energy consumption and production costs. By precisely controlling aggregate moisture content with the Xtrem® Probe, producers can optimize energy usage and reduce overall production costs while maintaining quality standards.

(5) Water / Chemical Addition:

During concrete and asphalt production, the addition of water or chemicals is carefully controlled to achieve desired mix properties. The Xtrem® Probe facilitates precise control of water and chemical addition by providing real-time moisture measurements of aggregates. Producers can adjust the amount of water or chemicals added based on current moisture levels, ensuring consistency in mixtures and optimizing performance. This level of control enhances product quality, reduces material waste, and contributes to overall process efficiency.

(6) Storage:

Proper storage of aggregates is vital to preserving their quality and preventing moisture fluctuations before use in concrete and asphalt production. The Xtrem® Probe aids in monitoring and controlling moisture levels in stored aggregates, ensuring they remain within specified tolerances. By continuously monitoring moisture content, producers can take corrective actions if deviations occur, such as covering stockpiles during inclement weather or adjusting ventilation in storage facilities. This helps maintain the integrity of aggregates and prevents issues during subsequent production stages.

Key Advantages of the SONO VARIO Xtrem Aggregate Moisture Probe

In summary, the SONO-VARIO Xtrem® Aggregate Moisture Probe offers unparalleled process control applications in concrete and asphalt production, enabling producers to optimize mix proportions, control moisture content, prevent segregation, reduce energy consumption, and improve overall process efficiency and quality control. Its advanced technology and precision make it an indispensable tool for enhancing productivity and ensuring the highest standards of quality in construction materials manufacturing.

Contact our experienced application engineers and uncover solutions for your instrumentation and data management needs.