Concrete Mixer Probe for Zero Slump Concrete

In the construction industry, ensuring the correct moisture content in concrete is crucial for achieving optimal strength, durability, and workability. This is particularly challenging with zero slump concrete, where the mixture has no measurable slump and is highly stiff. Accurate moisture measurement is essential to maintain the quality and consistency of the concrete. This is where the SONO-MIX Concrete Mixer Probe, based on TDR TRIME technology, comes into play, offering a reliable solution for precise moisture measurement in zero slump concrete.

Understanding Zero Slump Concrete

Zero slump concrete is a type of concrete that exhibits no measurable slump when tested using the standard slump test method. This type of concrete is often used in applications where high strength and low workability are required, such as in pavements, hollow-core slabs, concrete blocks, masonry products, precast concrete, and mass concrete structures. Due to its stiff nature, zero slump concrete presents unique challenges in measuring and controlling moisture content.

The Importance of Moisture Measurement

Accurate moisture measurement in zero slump concrete is vital for several reasons:

- Consistency: Ensuring uniform moisture content helps in maintaining the consistency of the concrete mix, leading to better performance and longevity of the structure.

- Strength: The water-cement ratio directly influences the strength of the concrete. Precise moisture measurement ensures that the concrete achieves its desired strength.

- Durability: Proper moisture content prevents issues such as cracking, shrinkage, and other durability problems.

- Cost Efficiency: Optimizing the moisture content can reduce material waste and improve the overall cost-efficiency of the construction process.

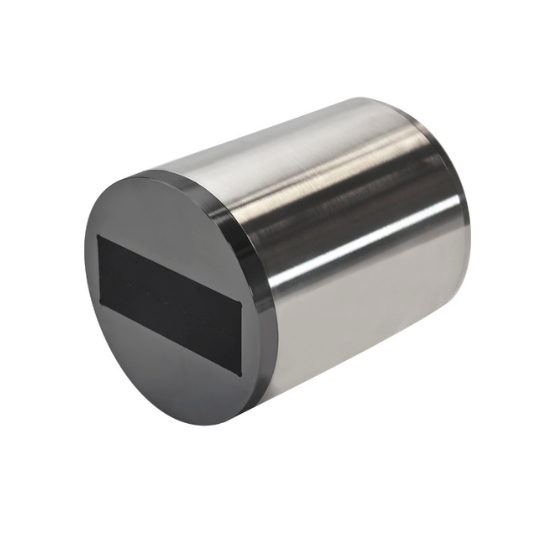

Introducing SONO-MIX Concrete Mixer Probe

The SONO-MIX Concrete Mixer Probe utilizes advanced TDR TRIME technology to deliver accurate and repeatable moisture measurements in zero slump concrete. Here’s how it stands out:

TDR TRIME Technology

Time Domain Reflectometry (TDR) technology, combined with TRIME (Time Domain Reflectometry with Intelligent Micromodule Elements), allows the SONO-MIX Concrete Mixer Probe to measure moisture content with high precision. This technology sends electromagnetic pulses into the concrete mix and measures the reflected signals to determine the moisture content.

Key Features of SONO-MIX Concrete Mixer Probe

- High Accuracy: The SONO-MIX Concrete Mixer Probe provides highly accurate moisture measurements, essential for maintaining the quality of zero slump concrete.

- Robust Design: Built to withstand the harsh conditions of concrete mixing, the probe is durable and reliable.

- Easy Integration: The probe can be easily integrated into existing concrete mixers, making it a versatile solution for various applications.

- Real-Time Monitoring: Continuous real-time monitoring allows for immediate adjustments to the concrete mix, ensuring optimal moisture content throughout the mixing process.

- Direct Installation: The SONO-MIX Concrete Mixer Probe is designed to be installed directly inside concrete mixers. This strategic placement allows for real-time control of the precise quantity of water added, ensuring the ideal concrete recipe is achieved every time.

Benefits of Using SONO-MIX Concrete Mixer Probe

- Improved Quality Control: With precise moisture measurement, the quality of zero slump concrete can be consistently maintained.

- Enhanced Productivity: Real-time data enables quick decision-making and adjustments, reducing downtime and improving overall productivity.

- Cost Savings: By optimizing the water-cement ratio and reducing material wastage, the SONO-MIX Concrete Mixer Probe helps in achieving significant cost savings.

Technical Considerations

- Calibration: Regular calibration of the SONO-MIX Concrete Mixer Probe ensures continued accuracy and reliability. Calibration should be performed according to the manufacturer’s guidelines and industry standards.

- Installation: Proper installation is critical for accurate moisture measurement. The probe should be installed at the correct location within the mixer to ensure representative sampling of the entire mix.

- Maintenance: Routine maintenance, including cleaning and inspection, ensures the longevity and performance of the probe. Regular checks for wear and tear can prevent measurement errors and equipment failures.

Conclusion

Accurate moisture measurement is crucial for producing high-quality zero slump concrete. The SONO-MIX Concrete Mixer Probe, leveraging advanced TDR TRIME technology, offers a reliable and efficient solution for this challenge. Its high accuracy, robust design, and real-time monitoring capabilities make it an indispensable tool for the construction industry, ensuring that zero slump concrete meets the highest standards of performance and durability. Designed for direct installation inside concrete mixers, the SONO-MIX Concrete Mixer Probe provides real-time control over water addition, ensuring an ideal concrete recipe every time.

Investing in the SONO-MIX Concrete Mixer Probe means investing in the future of concrete construction, where precision and quality are paramount. Embrace the technology that delivers excellence and transform your concrete mixing process with SONO-MIX.

For more information about the SONO-MIX Concrete Mixer Probe and how it can benefit your construction projects, review our product guide or contact us today.