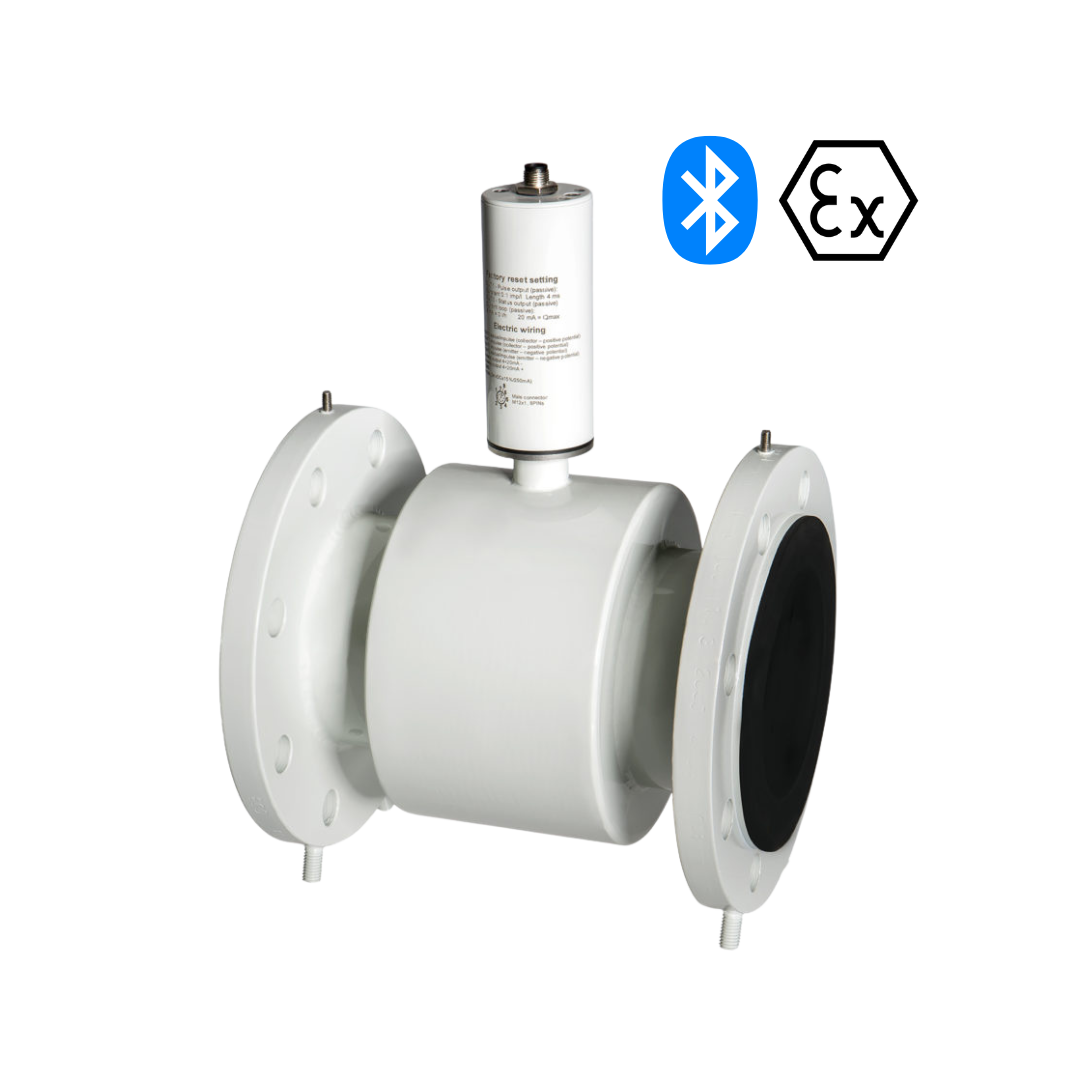

Electromagnetic Flow Meter – Flow 33

The Electromagnetic Flow Meter FLOW 33 without a display unit is the perfect solution for customers who require pulse or current signals from the meter without needing a display unit.

- Description

- Downloads

Description

Compact Electromagnetic Flow Meter FLOW 33 Without Display Unit

Overview of the Electromagnetic Flow Meter:

The Electromagnetic Flow Meter FLOW 33 without a display unit is the perfect solution for customers who require pulse or current signals from the meter without needing a display unit.

Key Technical Properties of Flow 33 Electromagnetic Flow Meter:

- Integrated Evaluation Unit: The evaluation unit is located directly on the sensor, simplifying the installation process.

- Robust Construction: Made from structural steel with options for full corrosion-proof construction.

- LED Indicators: Four informative LEDs on the evaluation unit indicate the meter’s status.

- Electrical Connectivity: Standard 8-pin M12 connector for easy electrical connection.

- Bluetooth Configuration: Configure the electromagnetic flow meter using Bluetooth communication with our dedicated Android/Windows software. Users can set up the flow meter using mobile devices such as phones or tablets directly at the installation site.

- Advanced Diagnostics: Perform simple diagnostics, simulate flow rates, and adjust settings, including two impulse contacts, one flow switch NO contact, status signal, and one 4-20mA current loop output.

- Flexible Electrode Options: Available with stainless steel, tantalum, or Hastelloy electrodes.

- Versatile Process Connections: Choose from flanged, inter-flanged, screwed, clamp, or threaded connections, suitable for various industries.

- Diverse Liner Materials: Options include hard and soft rubber, rubber certified for drinking water, PTFE, PFA, or E-CTFE.

Electromagnetic Flow Meter Working Principle:

The working principle of an electromagnetic flow meter is based on Faraday’s Law of Electromagnetic Induction. According to this principle, when a conductive liquid flows through a magnetic field, it generates a voltage proportional to the flow velocity.

Here’s a breakdown of the process:

- Magnetic Field Generation: The electromagnetic flow meter generates a magnetic field using coils located on either side of the flow tube.

- Voltage Induction: As the conductive liquid flows through the magnetic field, it induces a voltage.

- Electrode Detection: Electrodes placed inside the flow tube detect this induced voltage.

- Signal Processing: The induced voltage is directly proportional to the flow rate, and the signal is processed by the evaluation unit to determine the flow rate.

This method ensures accurate measurement of the flow rate without any moving parts, making it highly reliable and maintenance-free.

Applications of the Electromagnetic Flow Meter across Industries:

The FLOW 33 electromagnetic flow meter is versatile and can be used across various industries, including:

- Water Management: Ideal for water treatment plants.

- Food Processing: Suitable for dairies, breweries, and other food processing applications.

- Paper Industry: Reliable for paper manufacturing processes.

- Power Engineering: Used in power plants and energy sectors.

- Mining: Robust enough for use in mining operations.

The high sample rate ensures excellent repeatability (0.2%), making it advantageous for batching processes in filling machines and for transmitting flow rates to superior PLC systems without the need for a local display unit. Its sturdy construction ensures longevity, even under the harshest operating conditions.

Flow 33 Magnetic Meter Advantages and Disadvantages:

Advantages:

- High Accuracy: Provides precise flow measurements with excellent repeatability.

- No Moving Parts: Reduces maintenance requirements and enhances reliability.

- Wide Range of Applications: Suitable for various conductive liquids and industries.

- Flexible Output Options: Includes pulse, current, and Bluetooth communication for easy integration and configuration.

- Robust Construction: Durable design suitable for harsh environments.

- Corrosion-Proof Options: Available in full corrosion-proof construction for aggressive media.

- Easy Installation: Standard 8-pin M12 connector and various process connections simplify installation.

- Diagnostic Capabilities: Bluetooth-enabled diagnostics and configuration via mobile devices.

- Versatile Materials: Multiple options for liners and electrodes to suit different applications.

- Wireless Setup: Program the meter via Bluetooth.

- Ex Environment Certification: Certified for use in explosive environments with the following certifications:

- Ex I M2 Ex mb I

- Ex I M1 Ex ia I Ma

- Ex II 1G Ex ia IIC T6 Ga

- Ex II 1D Ex ia IIIC T85°C Da

Disadvantages:

- Conductive Liquids Only: Not suitable for non-conductive liquids such as oils or distilled water.

- Initial Cost: Higher upfront cost compared to some other types of flow meters.

- Installation Considerations: Requires proper grounding and installation to ensure accuracy.

- Power Supply: Requires an external power source for operation.

Product Highlights of Flow 33 Mag Meter:

- High Quality and Reliability: Ensures long-term performance and accuracy.

- Bluetooth Control: Easy setup and configuration with mobile devices.

- DC Current Output and Impulse Contacts: Flexible output options for various applications.

- Simple Electrical Connection: Standard 8-pin M12 connector.

- Corrosion-Proof Construction: Optional full corrosion-proof design for harsh environments.

- Rock-Steady Construction: Durable and reliable under heavy industrial conditions.

- Variable Mechanical Connections: Wide range of process connection options.

- Material Versatility: Multiple options for liners and electrodes.

- LED Status Indicators: Quick visual status checks.

- Easy Installation and Maintenance: User-friendly design with minimal maintenance requirements.

Experience the reliability and versatility of the Electromagnetic Flow Meter FLOW 33 without a display unit, the ideal choice for various industrial applications where precision and durability are paramount.