Revolutionizing Concrete Production with SONO-MIX©️ Sensors

Revolutionizing Concrete Production with Real-Time Moisture Measurement

Concrete production is a vital industry that serves a wide range of applications, including ready-mix and precast products. However, the traditional methods of measuring moisture and material composition in fresh concrete can be time-consuming, inaccurate, and delay the production process. SONO-MIX©️ sensors offer an innovative solution to this problem, revolutionizing concrete production with real-time, on-line measurement of fresh concrete moisture and electrical conductivity directly in the mixer.

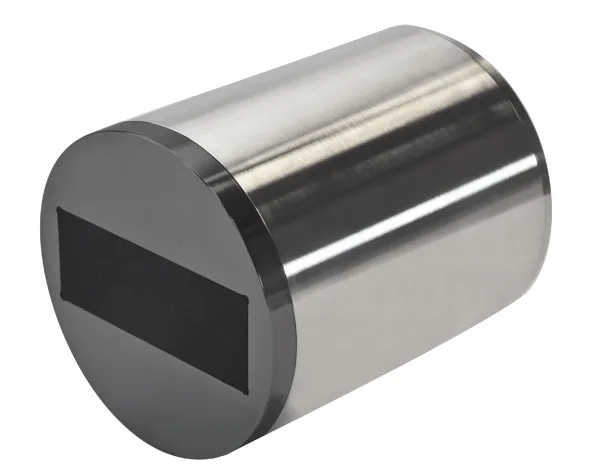

SONO-MIX©️ sensors are custom-designed probes and sensors that use the latest TRIME® TDR technology to provide high repeatability and accuracy. Seztec USA is a company with over 30 years of sensor development know-how and moisture measurement industrial experience. These sensors offer several features that make them an ideal choice for concrete production.

Real-Time Measurement

SONO-MIX©️ sensors provide real-time, on-line measurement of moisture and material composition in fresh concrete directly in the mixer. With the accurate measurement of these parameters, recipe errors can be prevented, leading to reliable quality control and higher cost-effectiveness. The sensors provide accurate real-time averaged moisture values at a rate of 4 per second, even in wet mixtures such as steel fiber concrete.

User-Friendly and Intelligent

SONO-MIX©️ sensors are user-friendly and intelligent. They can be easily integrated into existing batching control systems using analog output, and are compatible with the SONO-VIEW©️ display module. The sensors are available in two different lengths to fit the dimensions of your mixer and offer straightforward re-calibration in air and water when required.

Applications of SONO-MIX©️

SONO-MIX sensors find application in the concrete production industry, including ready-mix and precast. They are custom designed for on-line fresh concrete moisture and electrical conductivity measurement needs and can be installed on-line in the mixer. The sensors provide accurate and real-time measurement of moisture and material composition in fresh concrete, making them an ideal solution for quality control and cost-effectiveness in concrete production.

In conclusion, SONO-MIX©️ sensors offer an innovative solution to the problem of measuring moisture and material composition in fresh concrete. With their real-time, on-line measurement, these sensors provide reliable quality control and higher cost-effectiveness in concrete production. They are easy to use, compatible with common batching control systems, and provide accurate and real-time measurement in wet mixtures. With SONO-MIX©️ sensors, the concrete production industry can improve its efficiency and productivity, leading to better quality products and higher profits.

Contact us today for all your moisture measurement needs. today for all your moisture measurement needs.