Understanding Digital Signal Processing (DSP) in Ultrasonic Clamp-On Flow Meter

In the field of flow measurement, the transition from traditional methods to advanced technologies like the UF811 Ultrasonic Clamp-On Flow Meter, which utilizes Digital Signal Processing (DSP), marks a significant evolution. This article delves into the technical intricacies of ultrasonic signal processing, particularly focusing on the UF811 model, to highlight how DSP enhances the capabilities of these modern flow meters.

The Basics of Ultrasonic Flow Measurement

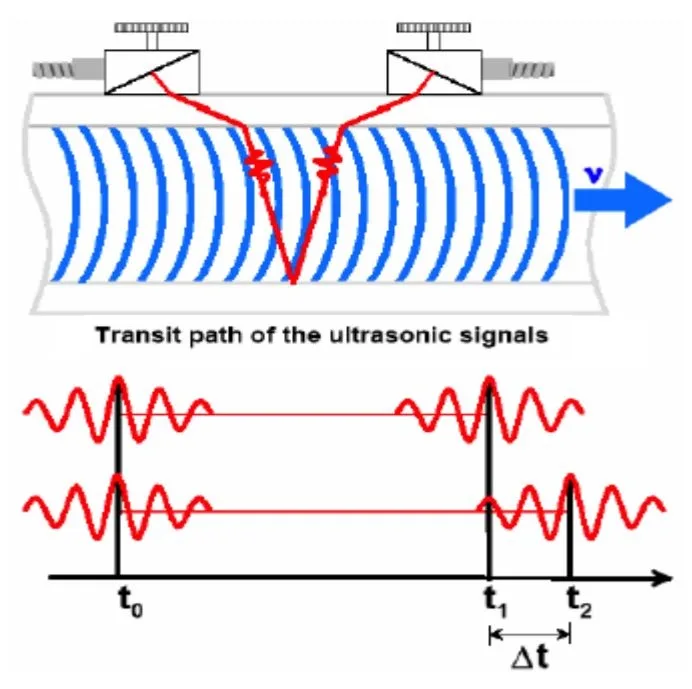

Ultrasonic flow meters, like the UF811, operate on the principle of measuring the time of flight of ultrasonic pulses. These pulses are transmitted and received by transducers mounted on the exterior of the pipe. The difference in transit times of these pulses, moving upstream and downstream with the fluid flow, is used to calculate the flow rate. This method is highly effective across various fluid types and conditions, making ultrasonic meters like the UF811 versatile for diverse applications.

DSP Signal Processing in UF811

The UF811’s efficiency and accuracy are primarily attributed to its DSP technology. Unlike analog signal processing, DSP in the UF811 involves converting ultrasonic signals into digital form, which are then processed using sophisticated algorithms. This digital approach offers several advantages:

- Noise Reduction: DSP algorithms in the UF811 effectively filter out background noise, crucial in industrial environments where external disturbances can impact measurement accuracy.

- Signal Quality Enhancement: The UF811’s DSP enhances signal quality, ensuring accurate flow measurement even in challenging conditions, such as low-flow scenarios or with fluids containing particulates.

- Velocity Profile Correction: The UF811 uses DSP to adjust for variations in the fluid’s velocity profile, ensuring accurate measurements across different pipe sizes and flow conditions.

Advantages of DSP Over Analog Signal Processing

The transition to DSP in devices like the UF811 offers numerous benefits over traditional analog processing:

- Accuracy and Reliability: DSP provides more precise measurements by handling signal distortions and eliminating electronic noise, a common issue in analog systems.

- Flexibility and Adaptability: The UF811 can be calibrated for various pipe sizes and fluid types, thanks to the versatility of digital processing.

- Advanced Diagnostics: DSP allows for enhanced diagnostics, enabling early detection of issues like sensor misalignment or signal quality problems.

- Real-Time Data Processing: The UF811 offers real-time processing, essential for dynamic flow management and immediate decision-making.

- Scalability and Future-Proofing: Digital systems like the UF811 are easily updated, ensuring long-term effectiveness as technology advances.

In conclusion, the UF811 Ultrasonic Clamp-On Flow Meter exemplifies the advancements in flow measurement technology through its use of DSP. This technology ensures that the UF811 provides accurate, reliable, and versatile flow measurements, making it an indispensable tool for a wide range of industrial applications. The UF811 stands as a superior choice in the realm of non-invasive flow measurement solutions, showcasing the future of ultrasonic flow metering technology.